Building diagnostics

Building diagnostics

We have extensive experience in planning, carrying out and assessing building diagnostics, even in difficult cases.

Among other things, we carry out damage mapping, potential field measurements, non-destructive determination of the concrete cover, soundings and the determination of chloride depth profiles with subsequent analysis in our in-house chemical laboratory to determine the corrosion condition of the reinforcement over a wide area. We prepare the results for you in a material test report in such a way that it can be used as a basis for repair or the evaluation of various repair alternatives.

We are also happy to support you with questions regarding carbonation-induced corrosion of the reinforcement, determination of concrete pressure or surface tensile properties as well as with the determination of the position of the reinforcement and the degree of reinforcement of existing structures.

Benefit from our research activities in the field of "Corrosion and corrosion protection of reinforced concrete" as well as in the field of non-destructive testing. Our scientific work and our activities in national and international expert committees ensure the best possible handling of your concerns.

We will be happy to advise you on the examination methods and, if necessary, combinations of different procedures that are best suited to your needs.

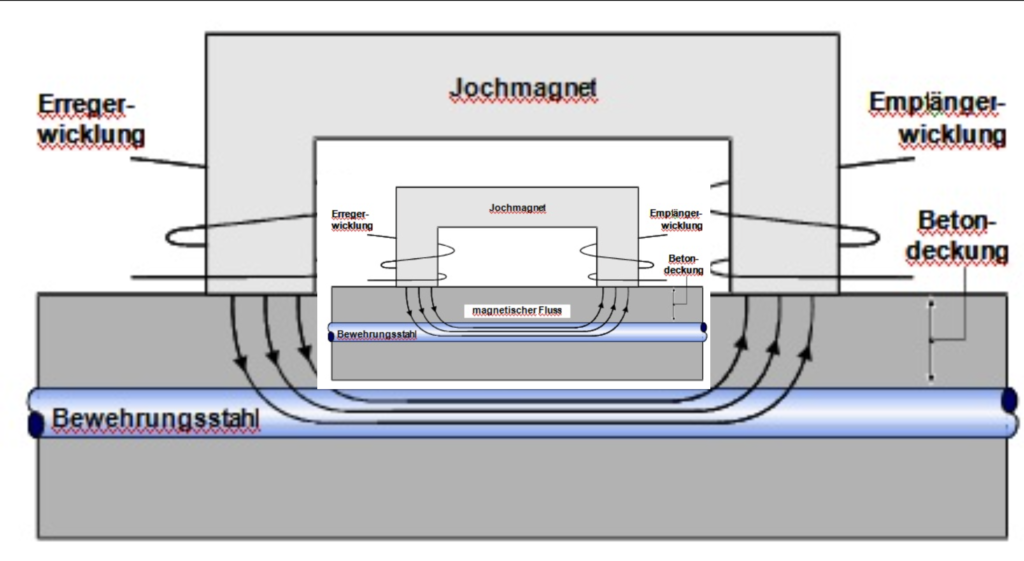

Schematic structure of an inductive measuring probe

Concrete cover measurement

The determination of the existing concrete cover, the position of the reinforcement and the existing bar diameters is an important part of the building diagnosis. In new buildings, the non-destructive determination of these parameters is mainly used for quality control of the construction work. In the case of existing buildings, knowledge of these parameters is required, for example, to calculate existing load-bearing reserves, to plan and carry out repair measures and to estimate the remaining service life. For this purpose, we apply the measuring principle of the alternating magnetic field method, which is based on the functioning of a transformer: An AC voltage is applied to the excitation coil so that an induction voltage is generated in the receiver coil. The magnitude of the induced voltage depends on the proportion and distance of magnetisable material in the direct vicinity.

After prior calibration in iron-free space, the thickness of the concrete cover can be inferred with a known diameter. If the concrete cover is known, it is also possible to estimate the bar diameter. However, these values should always be secured by a random check by means of sounding holes.

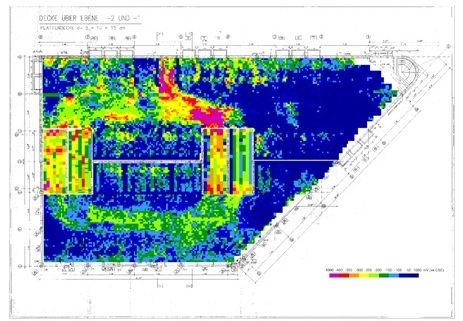

Potential field measurement

Chloride-induced corrosion of reinforcement is one of the most common forms of damage to reinforced concrete structures. If a critical chloride content is reached on the surface of the reinforcement, the reinforcement is depassivated and local potential differences of several 100 mV can occur. If there are favourable boundary conditions for corrosion (sufficiently low concrete resistance, sufficient oxygen at the cathode, etc.), anodic partial reaction occurs in the areas with the lowest potentials, with a corresponding reduction in the cross-section of the reinforcement. Particularly in the case of chloride exposure, such as occurs with regular exposure to de-icing salt in winter, critical cross-section losses can occur relatively quickly. The local distribution of the potential is thus an indication of depassivation and thus the risk of corrosion. The potential field measurement is a recognised method for illustrating the potential distribution.

The measurement is usually carried out by recording an orthogonal measuring grid with 15 to 50 cm measuring line spacing. For this purpose, single or multi-wheel electrodes are used for flat components and rod electrodes for supports or rising components.

Based on the results, locations for further investigations such as exploratory openings or chloride sampling can be determined on site.

Coloured representation of a potential field measured on a car park ceiling.

Determination of the carbonation depth using the phenolphthalein test

Determination of the carbonation depth

The corrosion resistance of steel in concrete is essentially a consequence of the high alkalinity of the concrete pore solution (pH > 12.6). At such high pH values, a passive layer (or oxide layer) forms on the steel surface, which almost completely prevents anodic iron dissolution. If the high pH value of the concrete drops to values below pH 9 due to carbonation, the corrosion protection of the reinforcing steel is no longer given.

The determination of the carbonation depth is carried out on a freshly produced concrete quarry surface, which is wetted with an indicator solution (phenolphthalein). In the non-carbonated area of the fractured surface, the indicator leads to a violet colouration of the concrete. Below a pH value of approx. 9, i.e. in carbonated concrete, the indicator remains colourless.

Chloride withdrawal

In order to assess chloride contamination, chloride depth profiles are created in practice depending on the task. Here, the chloride content of depth-staggered samples of drill dust is analysed and presented as a depth profile. The extraction of the drill samples takes place either on site with the help of a special hollow drill or in the laboratory by grinding drill core disks.

The subsequent determination of the chloride content of the samples is carried out in our in-house chemistry laboratory.

Drilling dust extraction device

Rebound hammer

Concrete compressive strength

Determining the concrete compressive strength of existing structures is a complex task. Exact results can be obtained by destructive testing of drill cores in the laboratory, but this requires considerable intervention in the structure of the component to be evaluated. Non-destructive methods, on the other hand, which infer the concrete compressive strength by correlation with other building material parameters, e.g. surface hardness (rebound hammer), surface tensile strength or the sonic transit time, are subject to greater uncertainties.

The best solutions can usually be achieved through a combination of destructive and non-destructive methods.

We will be happy to advise you on your particular issue.