Polymer materials

In the research field Polymeric Materials, new fundamental knowledge and skills are developed through scientific materials research, and the know-how and technical prerequisites are created to be able to work on the questions of application-oriented materials development at the ibac.

The working group Polymer materials also oversees chemical and instrumental analytics. More→

Are you interested in innovative chemical research with direct application? Why not join us as a student assistant or researcher? Click here to see offers not only for chemists.

Information about current developments, publications and team news

Biobased Building Materials

Nature provides an impressive variety of materials in large quantities, many of which remain unused. Each of these materials has a unique combination of properties that offer enormous potential for the development of new materials. Nevertheless, many of these resources are either thermally recycled or disposed of at considerable expense instead of being sustainably integrated into the value chain.

Our research focuses on developing innovative methods for the raw material and material utilisation of biogenic residues. We concentrate on materials that are produced in large quantities by nature but have hardly been used as raw materials to date and do not compete with food production. Our main sources include poultry feathers, crab shells, insect exoskeletons and grasses. Through targeted chemical processes, these raw materials are broken down, modified and further processed in such a way that they become economically viable. This not only opens up new applications, but also improves the carbon footprint and supports the transformation to a society based on renewable raw materials.

One example of the successful utilisation of biogenic waste materials is our sustainable hydrophobic coating for wooden surfaces. Wood is experiencing a renaissance due to increasing environmental awareness, but it needs protection from moisture, UV radiation and contamination. Our coating is based on chitosan, which is obtained from waste products from the food industry. In addition to protecting against moisture and UV radiation, our chitosanitaconate coating also offers increased fire resistance. Untreated wood usually burns completely after ignition, even without a continuous external heat source. Our new coating, on the other hand, makes the wood more resistant to flames. Even a single coat of the coating reduces the burning rate by a third. Multiple coats cause the wood to extinguish itself as soon as the external flame is removed.

Another example is our results with protein hydrolysates from poultry feather waste for the production of flame-retardant fibreboards. Wood fibres impregnated with these proteins show a significantly reduced decomposition rate in the range between 300 and 450 °C, as measured by thermogravimetric analysis. The final combustion of the impregnated fibres shifts by 50 °C to the range of 450 to 500 °C and occurs gradually, rather than immediately as with untreated wood. Even with a protein content of approx. 10% by weight, the boards produced using the wet process are self-extinguishing and show only minimal afterglow. In three-point bending tests, these fibreboards withstood loads of up to 15 N/mm², which complies with the DIN EN 622 standard for commercial, formaldehyde-bonded fibreboards. This proves that recycled protein hydrolysates not only have impressive flame-retardant properties, but can also be used as a completely sustainable binder for a new generation of ecological fibreboards. As these boards are made exclusively from natural materials, they can be shredded and composted after use.

Contact person: Nils Münstermann, Paul Marten, Fabian Weitenhagen, Lena Schmitz

Current projects: Biobased polyester resins for thermoforming (BioHarz) ❖ Glass bonding with biogenic residues ❖ Felt glides ❖ Sustainable chipboard panels

Completed projects: Biocomposite material❖ Biobased coatings and adhesives for wood ❖ Biosuperabsorber ❖ Recycled foams ❖ KeraSan ❖ bio-based compounds ❖ Chitin-based bioplastics ❖ Building material from feathers ❖ Fire protection wood

Gels in Building Maintenance

The preservation and renovation of existing buildings is a key challenge in modern construction. Conventional methods often require extensive intervention in the building fabric and involve considerable material expenditure and high costs. Hydrogels – three-dimensional, water-swellable polymer networks – offer a resource-saving alternative here. Hydrogels are highly adaptable and are therefore already being used successfully in industry.

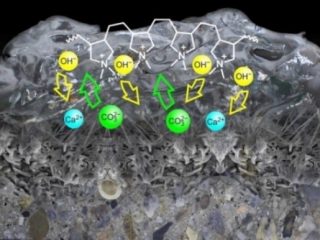

In addition to moisture regulation, hydrogels are also suitable for the restoration of reinforced concrete, which can be damaged by carbonation and chloride ingress. Highly alkaline hydrogels offer an innovative approach here, as they use ion exchange mechanisms to remove carbonate ions from the pore structure and replace them with hydroxide ions, thereby restoring the original alkaline protection of the concrete. Their electrical conductivity also makes them useful as a coupling medium for electrochemical processes such as electrochemical chloride extraction (ECE). By specifically adjusting their rheological properties, they can be applied to vertical surfaces, in cavities or in fine cracks without running uncontrollably. Another advantage is their reversible application: once the restoration process is complete, the gels can be removed from the surface without leaving any residue.

Current research projects focus on specifically controlling ionic exchange processes in order to further improve the efficiency of hydrogels in building maintenance. In addition, work is being done to optimise water vapour and moisture sorption properties for different climatic conditions. Another goal is to develop scalable manufacturing and application processes to make hydrogels economically viable for large-scale industrial applications.

The integration of hydrogel technologies into the construction industry opens up new possibilities for sustainable building maintenance and renovation. The targeted modification of their chemical and physical properties allows flexible adaptation to specific areas of application, thereby opening up new perspectives for the resource-efficient use of existing buildings.

Contact person: Tim Mrohs

Current projects: Highly alkaline hydrogels for preventing carbonation related corrosion processes (Gelko)

Completed projects: Development of a cationic hydrogel for concrete restoration ❖ Development of a 2-component rehabilitation system for the treatment of crack flanks in reinforced concrete ❖ Chloride extraction with hydrogels

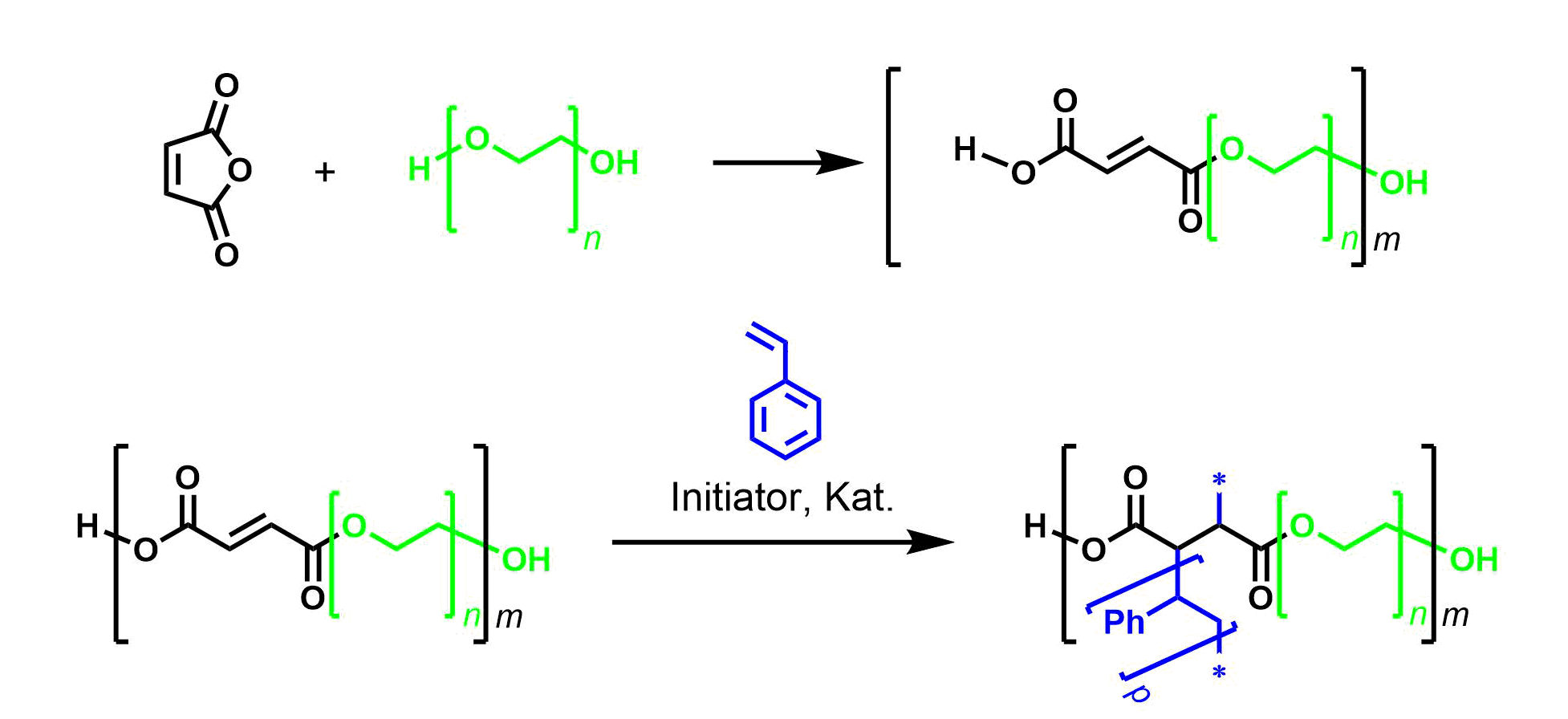

Ion conductive polymers

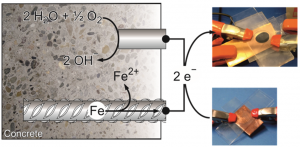

Electrically and ionically conductive polymer materials based on polyethylene glycol and lithium salts not only play a central role in the energy industry, but also have great potential in the construction industry. The electrical properties form the basis of our application-oriented material development with the current focus on electrochromic detectors and polymer sensors in their applications for the detection of reinforcing steel corrosion.

Within the focus "Ion-conductive polymers", the main work for us chemists is in the area of preparative and applied polymer chemistry and we use the methods of "classical" chemical structure elucidation, such as NMR, IR or DSC. In addition, we use typical electronic measuring methods, impedance spectroscopy (EIS) and cyclic voltammetry. In the sense of interdisciplinary technology transfer, we transfer chemical facts to problems from the engineering field and thus make a significant contribution to the further development of the solution-oriented strategy pool.

Contact person: Prof. Oliver Weichold

Current projects:

Completed projects: Development of an in situ manufactured multi-ring electrode for depth-graded monitoring of moisture behaviour in concrete components ❖ Electrochromic components for use in a corrosion or CCP monitoring system ❖ Development of a system for permanent monitoring of corrosion in reinforced concrete components based on novel injectable polymer sensors

Job offers

Theses (Chemistry, Civil Engineering, UIW)

Looking for a Bachelor's or Master's thesis? If you are interested in one of our topics, please get in touch with Nils Münstermann or one of the above contacts for a non-binding discussion.

Research practicals (Chemistry M. Sc.)

Students on the Chemistry (M. Sc.) course can carry out the freely selectable research internship with us. If you are interested in one of the above-mentioned research areas, please contact the responsible contact person, Nils Münstermann , directly or come by for a non-binding discussion by appointment.

Student research projects (UIW)

We offer students on the environmental and technological aspects of our key research areas the opportunity to carry out student research projects in environmental engineering. Please contact Nils Münstermann directly if you have any questions about the topics or a more precise definition.